Super cabin sound proofing meaning?

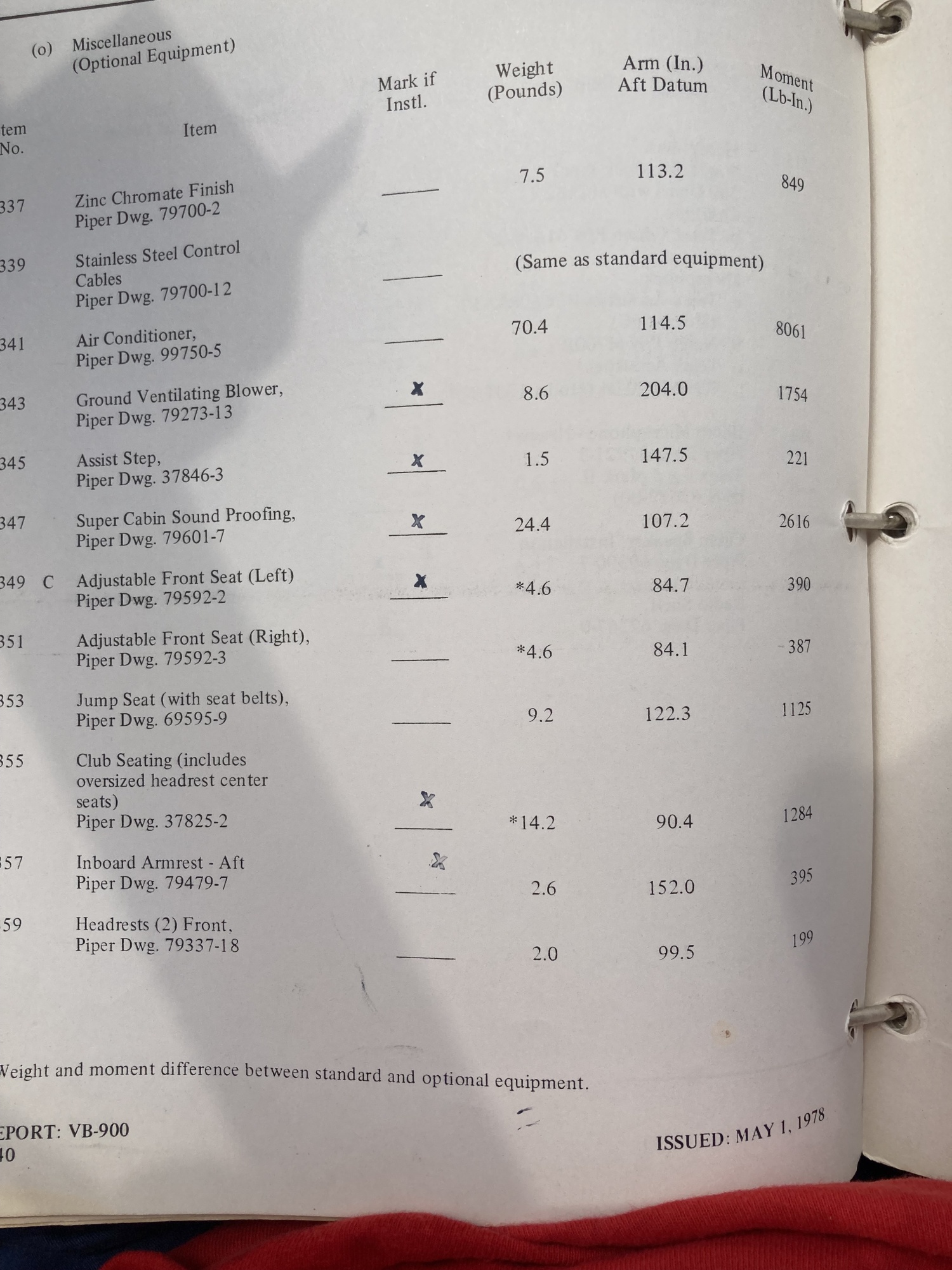

I was looking at my equipment list and noted it super cabin soundproofing was installed. What did Piper consider to be super sound proofing? I’m assuming it’s some sort of insulation. But did that also include thicker windows?

I own and fly a 79 PA32RT-300T. Previous aircraft are a 79 Archer and 76 Arrow.

Comments

This OEM option was on my 1980 Warrior. The only thing that appears to reflect this is a thin layer of yellow insulation in the side walls and the ceiling. Oddly enough, my Warrior only had a connection setup for a head set on the pilots side. I have never understood why anyone would not put a copilot plug in into the dash. Maybe there was a connection between the sound proofing and a headphone plug for the copilot. i.e. the sound proofing made it so quiet in the cockpit that you did not need a headset??

When I started flying in the 70's, we just did not use headsets. The planes were not any quieter then now. It was not easy communicating with the instructor or ATC, but we just accepted it as normal.

This is nothing more than a layer of fiberglass insulation with a layer of plastic on one side. I replaced all that with a sponge like sound deadening material encased in two heavy layers of aluminum foil--Soundex.

After the change, the plane is much quieter and has better insulation. When I was doing the changeover, I found several areas where the insulation was soaked with water from leaks in the airframe.

Airtex sells a TSO'd sound proofing insulation as part of their interior refurb kits. It is a 3/8" thk closed cell black foam (I think it's like a light weight neoprene) with an aluminum foil on one side and peel-n-stick on the other. I replaced all the fiberglass insulation in my 74 Archer w/ this product and I couldn't tell if it lowered noise levels much, but w/ a headset it doesn't matter. I imagine w/ this material adhered to the airframe skins, it would at least absorb some vibration

Pull all the wall panels out, then pull the fiberglass out, then cut each piece of foam into shapes that fit within the fuselage rib shapes. Then pull the adhesive backing and spray the sticky side w/ mineral spirits so it won't stick to your fingers and the aluminum. Put the piece in place then press firmly. The mineral spirits will eventually off-gas so that the adhesive does it's job. Trust me, this stuff sticks to EVERYTHING so be careful. When it's all done, I'm guessing that you've added maybe a pound or two to your gross wt. It's not expensive material. The job is time consuming and you should do it in a hangar or when the weather is nice if outdoors.

'74 Archer- New Owner, old 120hr. Student pilot. Self-taught gearhead